RF System Design

Enecell has over 20 years of experience identifying the performance criteria required to meet customer and regulatory requirements for RF products. From challenging receiver rejection parameters to critical power and spectral mask requirements, Enecell can create a list of electrical specifications your team needs to design against.

RF/Analog Circuit Design

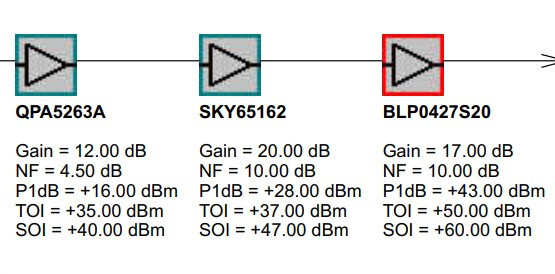

After a system design is in place, Enecell can design the individual subsystems of the RF chain to support your team as needed. High linearity RF receivers, low phase noise oscillators, high power transmitters, along with up/downconverters as needed per the specifications. Enecell can propose options for different budgets and time to market, and select components and designs conducive to the intended manufacturing environments of our clients.

Automated RF Test/Measurement Equipment

Enecell can provide turn-key measurement equipment that enables the evaluation of products from the early design stages through production. During conceptual design and prototyping phases, engineers often need a way to perform iterative tests that evaluate the performace of a circuit over temperature, voltage, or a non-ideal impedance. Enecell has produced numerous VSWR simulation devices along with software to control them. Encell uses a TEM cell to evaluate potential points of concern for unintentional emissions or susceptibility.

For the production environment, many manufacturers prefer to have an incremental investment in their test solution. Often times a product needs a cost-conscious answer for test and alignment but higher investments are deferred until market acceptance of the product has been reached. We've worked with clients in all stages of product lifecycle to develop RF test and alignment equipment or systems comprised of standardized RF test equipment.

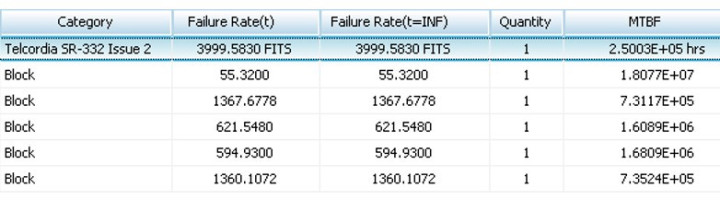

Reliability and process capability studies

An MTBF study is only as accurate as the data used to perform the analysis. From maximum applied voltage on a capacitor to understanding the thermal resistance of a PCB that takes heat away from an active device, Enecell has performed reliability studies with detailed consideration of component stress parameters unique to the product that is being designed. Enecell can offer suggestions to improve MTBF in many instances.

In the production environment, challenges are often encountered when a product has a critical transmit power specification but is limited by FCC/ETSI regulations. Variations in production measurements in a process capability study could indicate likely opportunities for nonconformance. Enecell can offer suggestions on how to improve product yields through changes to the product design, test limits, or the calibration and selection of test equipment.

Enclosure Machining

Enecell has CNC router for machining plastic enclosures or metal engraving of control panels for a professional appearance on your prototypes. Enecell can offer this service for our low volume turn key products as well.

HVACR Control Systems

Encell has maintained a close partnership with a key HVACR contractor. Enecell has helped to solve many unconventional control systems needs in this industry to enable our client to be a differentiator. From a special control system to allow safe entry into walk-in freezers, to a modernized replacement controller on an obsolete ice machine, Enecell has developed electronic solutions and manufactured them as needed for our client to use as part of their installation and repair services.

Capabilities

Enecell has used a variety of software tools for design and analysis, with most of our experience in using the platforms listed below. All trademarks are property of their respective owners.

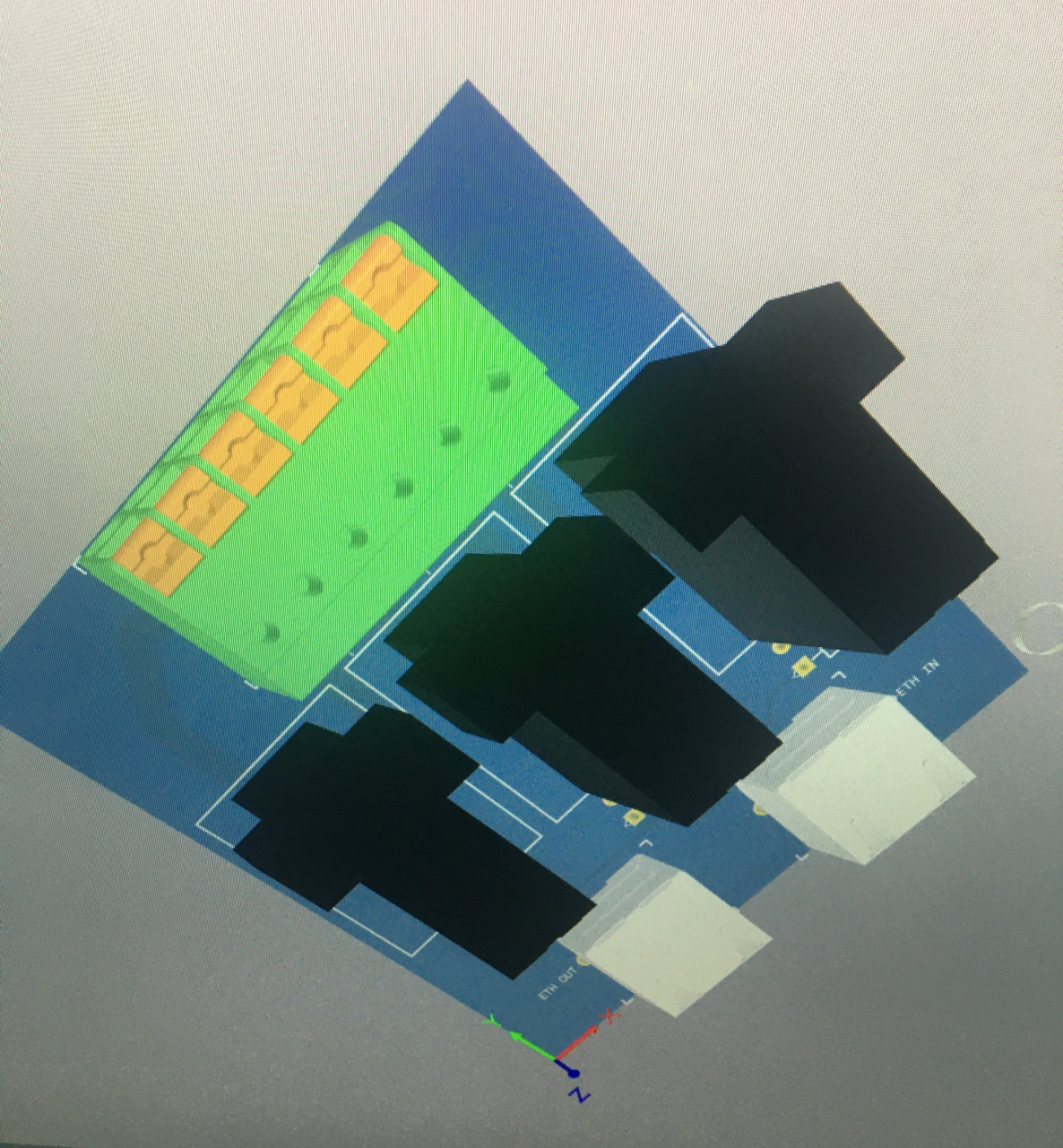

Altium Designer

Mentor Graphics PADS

Cadence Orcad

Keysight Pathwave

Reliasoft Lambda Predict

National Instruments Labview